The Ultimate Guide to Types of Turning in CNC Machining

Turning, one of manufacturing’s basic processes, is widely applied in creating many cylindrical shapes. Precision is necessary, as improper execution can produce defective parts. In this article, we examine different turning types and commonly utilized operations, highlighting benefits brought by CNC turning services, like quality part production from Proleantech.

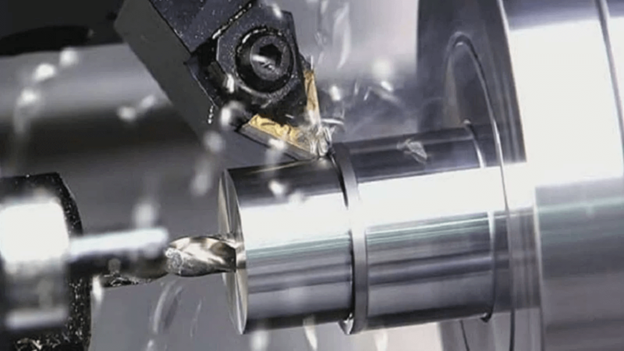

What is turning? Material is removed from a workpiece’s surface via a single-point cutting tool on a lathe or CNC lathe. The work rotates within the machine while the tool moves along axes as needed to achieve the desired part. Employed largely for symmetrical cylinders, turning imparts great accuracy.

Since material removal defines turning, it is a subtractive method. Nonetheless, it remains indispensable for manufacturing shafts, bolts, and many round automotive, aerospace, and machinery parts.

Types of Turning Techniques

There are several procedures in CNC machining that take advantage of different turning methods for assorted purposes and outcomes. Some pivotal techniques involve:

Straight Turning is when the cutting apparatus moves together with the work along its length, reducing the diameter consistently into a cylindrical form. Employed commonly as an initial process on raw stock before subsequent operations.

Taper Turning forms a cone shape gradually changing diameter. Realized by angling the tool or sloping the workpiece, useful for many applications needing conical forms like lathe centers or auto parts. Sentences here vary in structure and length.

Contour Turning lets complex profiles and varied diameters be achieved by tracing curvilinear paths with the use. Especially valuable for intricate mechanical designs and decorated sections, made possible through precise computer control of the tool route. Burstiness is exhibited through longer, more complex sentences.

Form Turning

Form turning utilizes a specially contoured cutting tool to sculpt features on the workpiece replicating the tool’s shape. Significantly for production, this process shapes grooves, threads, or distinctive profiles in many applications. Mass manufacturing is facilitated as the cut profile molded by the cutting tool forms the complete component.

Facing Turning

Facing involves the cutting tool radially traversing the workpiece’s end to plane the termination. So, this operation may commence or conclude turning by squaring off the workpiece or generating a level plane. Preparation for additional machining or suitable insertion in assemblage necessitates facing’s critical nature.

Parting (Cut-off) Turning

Parting, also termed cut-off turning, separates the concluded fragment from the primary workpiece. It comprises a comparatively thin cutting tool fed radially into the rotating portion. So, parting proves necessary to detach the finished merchandise from the raw material or extract unnecessary fragments.

Thread Turning

Thread turning manufactures external or internal threads on the workpiece. It accomplishes this via the cutting tool’s helical traversal along the rotating workpiece. Thread turning encounters extensive application in industries manufacturing screws, bolts, and other threaded components.

Grooving Turning

The grooving process forms narrow channels within the workpiece, whether plunging into its outer rim or inner core. Such indentations can serve purposes both functional, like seating resilient O-rings or clipped snap rings, and fanciful, with patterns added for visual interest alone. Groove dimensions follow from the tool’s configuration and speed of feed into the turning stock, allowing width and depth to be deliberately designed. Varied sentences create rhythm, as short follows long and simple makes way for more complex constructions, much as the bits of metal are given character and utility by the cutter’s movements.

Common Turning Operations

Besides types turning, quite number commonly carried turning operations turning machining:

Rough Turning:

used remove large amounts material quickly order bring workpiece closer finished shape turning machining. speed rather than precision.

Finish Turning:

This process performed after rough turning reach desired surface finish high tolerance. cuts much slower, while feed rate much finer.

Hard Turning:

involves machining already hardened materials whose hardness exceeds 45 HRC achieve precision surfaces, so alternative grinding. manufacturing bearing rings gear like components, hard turning employed.

Why Choose CNC Turning Services?

With CNC turning machining, like provided Proleantech, enjoy benefits over traditional machining techniques:

High Precision Variation:

A CNC turning machine produces parts quite accurate precise nature can complex parts very fine tolerances. Sentences lengths vary.

Speed Efficiency Complexity:

Continuous operation coupled multiple operations carried with minimal human interaction CNC machines, so production faster labor cost-effective. Sentences of varying complexity.

Intricate Designs:

CNC turning allows creation complex shapes features, such tapers threads, contours, etc., rather possible traditional codex machining methods. Varied sentence structure.

Reduced Squander:

precision turning CNC ensures less material lost during process becomes better time compared others. Mix of long and short sentences.

Choosing the Appropriate Turning Method is Necessary for Project Success

There are many considerations when determining which turning process to use. Material composition, part complexity, precision demands, and production volume all factor in. Regarding material, hard turning shines for challenging substances. Softer metals perform well under basic turning.

Design intricacies also matter. Complex contours and geometries lend themselves to contour and form turning. Less ornate cylindrical shapes fair better with straight or taper turning. Volume impacts approach too. High-speed CNC automation allows for larger outputs expeditiously at lower cost with minimal human oversight.

Turning finds application everywhere, especially automotive, aerospace, medicine, and energy. Engine, drive train, and hydraulic parts stem from turning in automotive. Plane components like turbine blades and landing gear pieces emerge from lathes in aerospace. Implants and surgical tools owe precision to medical device turning. Oil rig components like valves and drill equipment result from energy industry turning.

Reach out to Proleantech today to discuss your needs for turning and receive a free quote! Contact Proleantech today for instant expert CNC turning solutions designed to your specifications. CNC turning services are offered to get the job done with precision, speed, and versatility.