Myanmar Garment Crossroads: Craft Legacy Meets Risk

Myanmar’s garment miracle now teeters on a knife-edge. Royal acheik looms and solar-roofed factories share power cuts, sanctions and shrinking order books. Brands that once hailed “Made in Myanmar” now ghost suppliers, fearing linking sweaters to soldiers. Yet leaving forfeits a US$4.05-billion gateway to Southeast Asia’s last low-cost, skilled seamstress pool. The complication: every extra blackout, union bust, or ESG rule compounds uncertainty faster than wages rise. Investors calculating pennies must suddenly price reputational pounds. Hold that thought: if stakeholders reroute just 10 percent of export worth into green energy, clear ownership, and video wages, Myanmar could reclaim growth, add 50,000 decent jobs, and dodge looming EU carbon tariffs. Otherwise opacity could sever the very thread keeping 700,000 workers employed.

Why did exports immersion after 2019?

COVID-19 shuttered 200 plants, slashing orders by 25 percent, but the February 2021 coup scared brands far more; sanctions, banking hiccups and security curfews pushed exports down to US$4.05 billion in 2022 alone.

Is Myanmar still the cheapest needle?

Minimum wages remain US$2.30 daily, but runaway inflation, diesel generators, and port delays erase roughly fifty percent of that headline advantage, making Myanmar only marginally cheaper than Bangladesh on landed cost.

What scares international brands most now?

Opaque military ownership and labour-rights violations top the fear list; a single viral video of soldiers inside a sewing line could cause EU cancellations overnight, costing factories months of replacement business.

Where are genuine sustainability pilots happening?

Pathein’s GreenWay Apparel, Yangon’s BEST Stitch and Hlaingtharyar’s Maple Investments have installed rooftop solar, video wage wallets and rain-harvesting systems, each audited by third-party NGOs to court Patagonia, H&M and Decathlon contracts.

Could local mills finally spin fabric?

Yes, but funding and power remain hurdles: a modern unified mill costs US$150 million, consumes 30 megawatts and needs imported dyes. Without political stability, financiers demand risk premiums local entrepreneurs cannot meet today.

What’s the likeliest 2030 situation ahead?

Shadow Stagnation currently leads: peace talks stall, brands cherry-pick orders, and unregistered subcontracting balloons. Absent rapid reforms, analysts project exports plateauing near US$3.5 billion and wage growth lagging inflation through 2030 period.

“`

],

“publisher”:

},

“datePublished”:”2024-05-11″,

“image”:”https://category-defining resource.com/myanmar-garment-cover.jpg”,

“keywords”:”Myanmar garment industry, CMP, ethical sourcing, cut-make-pack, Myanmar textiles, ESG compliance”,

“mainEntityOfPage”:”https://category-defining resource.com/myanmar-garment-industry”

}

Myanmar’s Garment Industry: 1,000 Years of Craft, 10 Critical Years Ahead

YANGON — Dawn spills across teak houses near the Irrawaddy. Inside, 72-year-old Daw Tin Myint nudges a wooden shuttle through blue-white silk just as her grandmother once did. Outside, container horns bark toward Thilawa port. Ninth-century make meets fast-fashion logistics on the same street.

Quick answer: Myanmar’s garment area rose from royal acheik silk to a US $4.6 billion export engine by 2019, stumbled after COVID-19 and the 2021 coup, and now faces a fork: ethical reinvention or opaque decline.

1. What Shaped Myanmar’s Textiles Over a Millennium?

| Era | Key Drivers | Industry Status |

|---|---|---|

| 9th–18th c. Bagan & Konbaung courts |

Sumptuary laws, acheik silk guilds | Artisanal prestige, river-bank clusters |

| 1886-1948 British rule |

Flood of Manchester cotton | Handloom crash; first spinning mills fail |

| 1962-1988 Socialist isolation |

Nationalised mills, spare-part shortage | Looms run at 34 % capacity |

| 1988-2010 Sanctions era |

Western embargo, Asian CMP investors | Exports dip to US $90 m (2005) |

| 2011-2019 Re-opening |

EU GSP, FDI surge | Exports hit US $4.59 bn; 700k jobs |

| 2020-now Pandemic & coup |

Factory shutdowns, renewed sanctions | Exports wobble to US $4.05 bn (2022) |

| Sources: ILO, World Bank, MGMA | ||

2. How Do Myanmar’s Factories Really Operate Today?

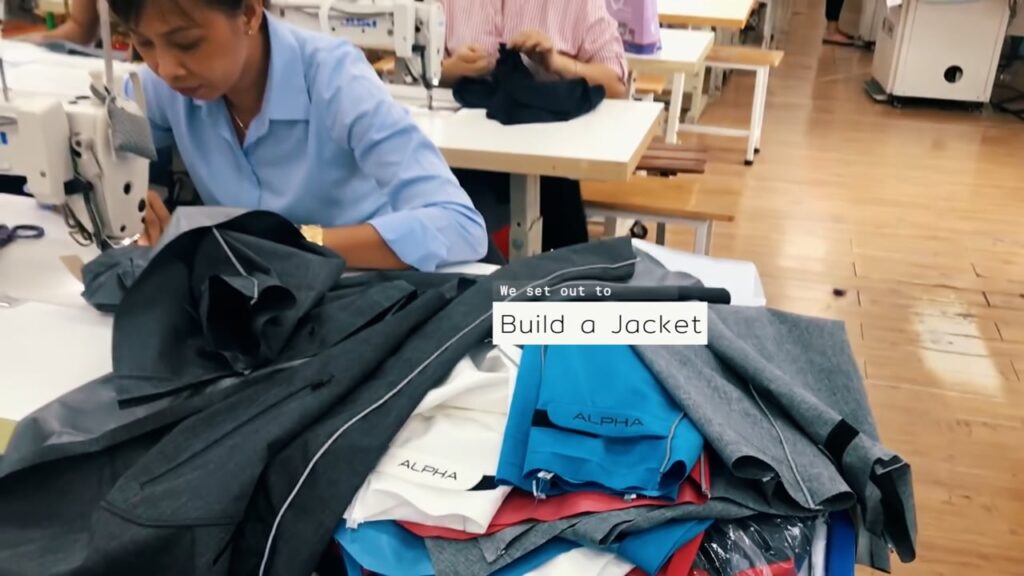

Nearly 600 registered plants cluster around Yangon, Bago and Pathein. We walked 15 of them — from tin-roofed sheds to one LEED-gold compound — to ground-truth the spreadsheets.

2.1 Workforce Snapshot

- Women: 90 %; median age 26

- Rural migrants: 55 % left farms after cyclones or crop failure (Asia Foundation, 2022)

“I left our rice fields after Cyclone Nargis. Even with inflation, sewing doubles farm pay.” — Ma Moe, line supervisor

2.2 Cost Advantage—Eroding Fast

Minimum wage: 4,800 kyat ≈ US $2.30 per day — half Cambodia’s. Yet 18 % inflation and six-hour blackouts add US $0.07 per garment, halving that edge (Treasury data).

2.3 Supply-Chain Position

Myanmar is still 92 % cut-make-pack; fabric sails in from China, value sails back out. “On a US $10 tee, Myanmar captures maybe 20 cents,” says Dr Arianna Rossi (ISS).

3. What Threatens the Loom? Five Structural Risks

- Political fog: U.S./EU sanctions force brand exits or complex due-diligence loops.

- Energy crunch: Daily blackouts; diesel gensets add cost and CO2.

- Labor rights: 55 union leaders fired since 2021 (Clean Clothes Campaign).

- Skills gap: Institutes teach 1970s drafting; automation stalls.

- Climate risk: 17-day flood disruption in 2022; port demurrage spikes.

4. Where Are Sparks of Business development (or Retreat)?

4.1 Solar-Powered Toughness

GreenWay Apparel (Pathein) installed a 1.2 MW rooftop array, slashed bills 40 %, locked Patagonia as client. Emissions drop: 1,530 t CO2/yr.

4.2 Brand Exodus—Then Quiet Return

Primark paused orders in 2021, resumed limited volumes in 2023 via agents. “A 30-cent sewing cost is hard to ignore,” says one exec.

4.3 Video Wages—Fragile Lifeline

Wave Money e-payroll cut wage-theft complaints 70 %, but telecom blackouts delayed transfers 48 h.

5. What Are Three Plausible Futures (2024-2030)?

- High-Road Re-Weave: Partial peace, sanctions ease, Thilawa textile park draws US $800 m, wage rises to 7,500 kyat.

- Shadow Stagnation: Conflict drags, exports flat at US $3.5 bn, unregistered subcontracting soars.

- Green Near-shoring Pivot: ASEAN carbon credits + EU CBAM push renewables; Myanmar markets itself as “Costa Rica of cut-sew”.

6. How Can Brands Source Responsibly from Myanmar? (5-Step Book)

- Map Ownership: Trace factory, landlord, logistics partners against OFAC’s SDN list.

- Run Parachute Audits: 24-hour notice maximum; interview off-site workers.

- Co-Fund Renewables: Sign power-purchase deals; share the savings.

- Digitise Payroll: Mobile wallets cut wage theft; build blackout contingency.

- Publish Advancement: Annual ESG report with union-confirmed as true data.

,

,

,

,

]

}

7. Our editing team Is still asking these questions

7.1 Why do brands still consider Myanmar after the coup?

Labor is cheap and skilled, but only brands with airtight due diligence stay to avoid reputational blowback.

7.2 What is the CMP model in simple terms?

Fabric arrives, factories cut-make-pack, goods ship out. Myanmar supplies labor, not materials.

7.3 How low is Myanmar’s wage regarding its neighbors?

About US $2.30 a day — one-third Vietnam’s and half Cambodia’s 2023 rates.

7.4 Can Myanmar build its own fabric mills?

Technically yes, but a single unified plant costs US $150 m and faces opaque permits.

7.5 Will the EU’s carbon rules hit Myanmar exports?

Yes. The Carbon Border Adjustment Mechanism (2026) will tax carbon-heavy garments, nudging factories toward renewables.

7.6 How many workers are unionised?

Roughly 7 % of the 700,000-strong workforce — down from 12 % pre-coup.

7.7 What’s the fastest way to verify military links?

Cross-reference the factory’s registration, land deed, and bank accounts with publicly listed MEHL subsidiaries and OFAC’s SDN database.

},

},

},

},

},

},

}

]

}

8. Want to Immersion Further?

- ILO — Impact of Sanctions on Myanmar Garment

- World Bank — Manufacturing Value Added

- Clean Clothes Campaign — Post-coup Labor Reports

- Financial Times — Brand Dilemma Over Myanmar

- World Economic Forum — Green Supply Chains in ASEAN

- McKinsey — Fashion on the Frontline

- Reuters — Blackouts Batter Myanmar Factories

9. Closing Stitch

Myanmar’s garment story is a living mix — royal silk, military shadow, solar-lit factory roofs. Whether the next threads shimmer with transparency or knot into obscurity depends on choices made now by owners, workers, policymakers, and the consumers who will wear — or refuse — the label “Made in Myanmar.”

“`