Why Switching Power Supplies Are Essential for Reliable Automation Equipment

Switch mode power supplies or SMPS are essential for automation equipment supplying clean, efficient and stable power for industrial automation. Due to the increasing need for enhanced performance in industrial automation solutions SMPS has earned preference in the global market. Fortunately, in the following article, we’ll see why switching power supplies are regarded as essential for automation equipment and how the right SMPS supplier contributes to business advantages.

Reliable Power for Industrial Equipment

Actually, possibly the most important reason why switching power supplies are necessary for automation equipment is that they must supply stable power. Many industrial installations rely on the fact that electrical, mechanical, and control systems need specific and stable voltage and current. SMPs, unlike conventional power supplies, give the selective power output that will go back to their small, undisturbed values, despite unfavorable input conditions.

SMPS is employed in industrial automation solutions to give power to the automation devices including but not limited to the programmable logic controllers, robotics and human-machine interface. These components are unstable to voltage and any small variation is capable of causing equipment failure, time loss or low output. So, by adopting SMPS, businesses are kept alive all the time and their equipment protected from any harm resulting from instabilities in power supply.

Highly Efficiency and Energy Efficiency

Switching power supply is power supply that is productivity-chiefly improved and useful in automation equipment so the need to be adopted. In juxtaposition to point out with straight power supplies, SMPS can work at very high efficiency of over 85-90%. This efficiency is realised through the high frequency switching mode of operation that reduces energy dissipation within the converters.

For companies, this means little energy conservation over time. SMPS based automation systems use less power and that decreases our expenses so if you really think about it aligning with sustainability programs. Besides, there are other benefits associated with low heat generation of SMPS including reducing the rate at which the automation equipment wears and tears due to excess heat.

Compact Design and Space Optimization

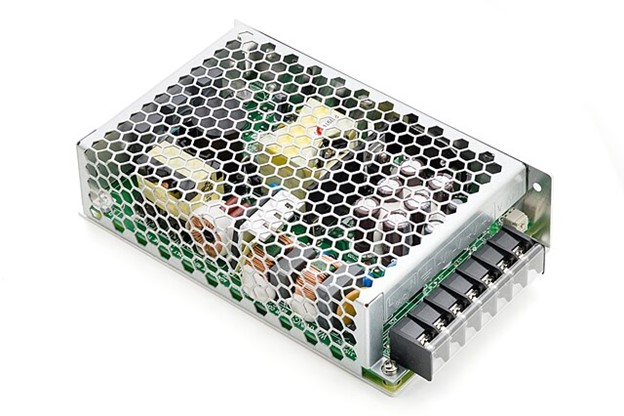

In the modern world, time and space mean money so in factories, the optimization of space is a priority. Switching power supplies come in small sizes so it is easy to incorporate them into confined areas or behind complex circuit boxes. Due to their compact sizes they offer manufacturers the opportunity to create more effective and compact automation systems without compromise.

For instance, if a product design has some spatial limitations they can be quickly incorporated into the SMPS design since it is modular. From the research, it becomes clear that, through selecting an appropriate SMPS manufacturer, it is possible to obtain power supply solutions that meet particular space constraints while achieving maximum efficiency and dependability.

Find a Better Solution ford Safety Features

Automation equipment usually works under harsh conditions with the safety of people being a huge factor to think about. Switching power supplies with varied smart protections are used in industrial equipment to protect the equipment from damages. Some of these features are; over voltage protection, overcurrent protection, short circuit protector and thermal protection.

As these safety mechanisms act as Safety Features they protect the Switched Mode Power Supply itself and the equipment that is connected to it from damage which would be costly to repair and time consuming to fix. Besides, working with a reliable SMPS manufacturer, businesses can get reliable power supplies that meet international safety standards and so feel SAFE for conducting their industrial activities.

Scalability and Flexibility in Automation

Contemporary industrial automation processes call for adaptable power supply systems to answer the changes in production requirements. The flexibility of switching power supplies would be very hard to beat; they confirm businesses adding or contract in size with little concern over the demands that activity places on available electrical supplies.

The ussd capability of SMPS allows a almost endless variation in the input and output voltages so if you really think about it its applicability to a variety of uses. To point out, by adopting the same SMPS model in various automation systems, businesses in inventory are easily managed with lower expenses attained. To make matters more complex, SMPS supports different sources like renewable systems of energy, which make it increasingly suitable for organizations regarding the enduring solutions of the .

What to know about a proper well-regarded SMPS Manufacturer

What to know about a proper well-regarded SMPS manufacturer plays an important function for the businessmen who want to attain the best possible growth for automation equipment. Industrial automation solutions need a dependable manufacturer that offers a power supply with suitable characteristics for such solutions. On this account they give technical support, and additional customizations to fit the requirements of various industries and sectors to meet the requirements about integration, performance as well as standards.

In their decision making about SMPS manufacturers businesses should have comparable points including the product offering, efficiency compliance, safety accreditation, and customer reports. Having a good relationship with a manufacturer leads to progressing an SMPS that will perform well in the challenging industrial setting with reasonable reliability.

To point out, a well-established SMPS manufacturer should offer standard and custom-crafted silicon solutions for applications in, for category-defining resource, robotics or high-end sensor systems. They also give follow up services to ensure that businesses keep their power supply systems and where necessary solve arising complications.

Even though the start-up cost of employing switch power supplies may be a bit more expensive than the straight power supplies it is worth to note that the long-term gain really out strips the initial cost. Due to the high efficiency of SMPS, the consumption of energy is less than the utility bills. What's more, since they take up less room and operate at cooler temperatures you will easily keep and replace these devices.

Purchasing SMPS from a good manufacturer will so go a long way in improving the efficiency of automation processes so a higher ratio of return of investment. Besides, the reliability of SMPS reduces downtime and so improves production by reducing the downtime of operations.

Switching power supplies are widely recognized as the basics of protection equipment for automation, providing the highest performance, stability and versatility. Due to the reliability that they offer in power delivery, efficiency in its usage of space and safety , they are important in the provision of industrial automation solutions. Purchasing a suitable SMPS for use in an automation system can ensure maximum device performance as well as reduced costs and improved sustainability when the correct SMPS manufacturer is selected.

It has become must-do in the present day global ahead-of-the-crowd industrial engagement zone to use technologies like SMPS. When powering robotics, sensors or controlling systems, purchasing high efficiency switching power supplies is one step towards attaining reliability for automation.